The centrifugal spray dryer offers highly efficient and effective drying. 95-98% of moisture can be evaporated almost instantly during the hot air flow stage. This is especially suitable for drying heat sensitive materials.

Spray drying is the technology most widely used in the liquid shaping process and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as: solution, emulsion, suspension and pumpable paste states.

| Specification | LPG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| Inlet temperature/℃ | 140-350 (automatically controlled) | |||||

| Outlet temperature/℃ | ~80-90 | |||||

| Maximum Drying capacity | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Centrifugal nozzle transmission mode | compressed air transmission | Mechanical transmission | ||||

| Rotating speed/rpm | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Diameter of spraying disc /mm | 50 | 100 | 120 | 140 | 150 | 180-340 |

| Heat supply | Electric heater | Electric heater and steam heater | Electric heater, steam heater, heat transfer oil | Others | ||

| Max. electric power /kw | 9 | 36 | 63 | 81 | 99 | |

| Dimension /m | 1.8×0.93 | 3×2.7 | 3.7×3.2 | 4.6×4.2 | 5.5×4.5 | Depends on actual conditions |

| ×2.2 | ×4.26 | ×5.1 | ×6 | ×7 | ||

| Dried powder collecting rate % | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

| Note: As for Drying capacity, material property, inlet and outlet temperature, please refer to the following diagram. | ||||||

| Model | A | B | C | D | E1 | E2 | F | G | H | I |

| 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 | |

| 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 | |

| 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 | |

| 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 | |

| 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 | |

| 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3050 |

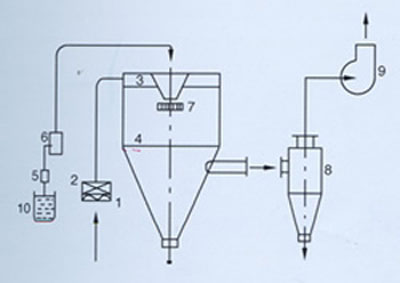

After been filtered and heated the air enters into the air distributor on the top of the dryer. The hot air enters into the drying room in the spiral form uniformly. Passing through the high-speed centrifugal sprayer on the top of the tower, the material liquid will rotate and be sprayed into the extremely fine mist liquid beads. Through very short time of contacting the heat air, the materials can be dried into the final products. The final products will be discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower.

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.

YIBU has been dedicated to providing comprehensive drying solutions for industries such as pharmaceuticals, food, chemicals, and new energy for nearly 30 years.

Read More